Stocksigns New Modern Slavery Signage Leads the Way in Construction

In the UK construction industry, where projects are fast-paced, workforces are transient, and supply chains are complex, a silent crisis often goes unnoticed: modern slavery.

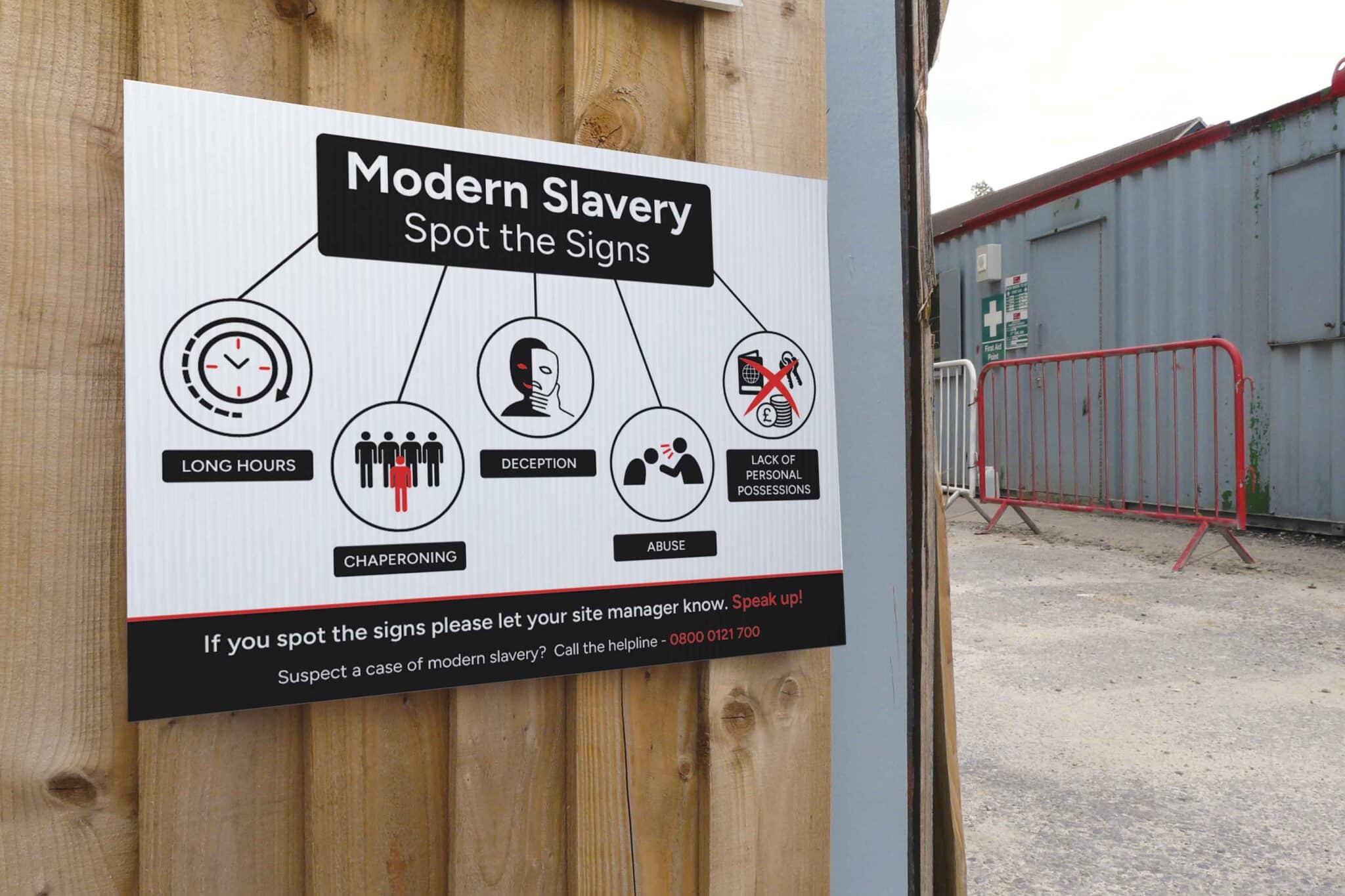

That’s why Stocksigns is proud to launch a new range of Modern Slavery Awareness Signs, specially designed for construction sites. These signs are more than just words on a wall they’re a frontline tool to help spot and stop exploitation.

What Is Modern Slavery, and Why Should Construction Care?

Modern slavery includes forced labour, human trafficking, and other forms of exploitation. It’s estimated that over 122,000 people are trapped in modern slavery in the UK, many in industries like construction where informal recruitment, language barriers, and subcontracting make abuse easier to hide.

Shockingly, labour exploitation in construction is on the rise. In 2022, the UK Modern Slavery Helpline saw a 53% increase in construction-related reports. That’s why awareness and early detection are key and signage can help.

How Can Signage Make a Difference?

Think of modern slavery warning signs like fire safety signs: they don’t solve the problem alone, but they alert, educate, and empower people to act.

Stocksigns new signage range is:

- Clear and simple, with easy-to-read language.

- Multilingual, helping reach non-English speaking workers.

- Strategically designed to prompt vigilance, offer reporting guidance, and point people to help lines like the Modern Slavery Helpline (08000 121 700).

- Customisable, so sites can include their own contact points or policies.

By placing these signs in worker areas, site entrances, welfare cabins and offices, employers show that they take safeguarding seriously and might just save someone from exploitation.

What the Experts Say:

According to the Stronger Together Toolkit for Tackling Modern Slavery in Construction, construction sites are especially high-risk due to:

- Use of agency and migrant labour

- Low oversight over subcontractors

- False credentials and unlicensed recruitment practices

- Workers living in overcrowded, unsafe housing, often provided by exploiters

The Toolkit recommends raising awareness among all staff and making it easy to report concerns. That’s exactly what these new signs do.

A Small Step That Sparks Bigger Change

Modern slavery thrives in silence. But with every sign placed, that silence is broken. Whether it helps someone recognise their situation or encourages a bystander to speak up, signage is a simple but powerful part of the solution.

At Stocksigns, we believe that everyone deserves fair, safe, and respectful work. By equipping construction sites with the right signage, we’re helping the industry take a stand and urging others to do the same.